A REIVEW ON PISTACHIO

As the team of La Recolte Du Monde Magazine, we visited Pistachio Research Institute in Gaziantep on April, 2019 and we hold a consultion. We submit our reivews on Pistachio for your consideration.

Have a pleasent reading!

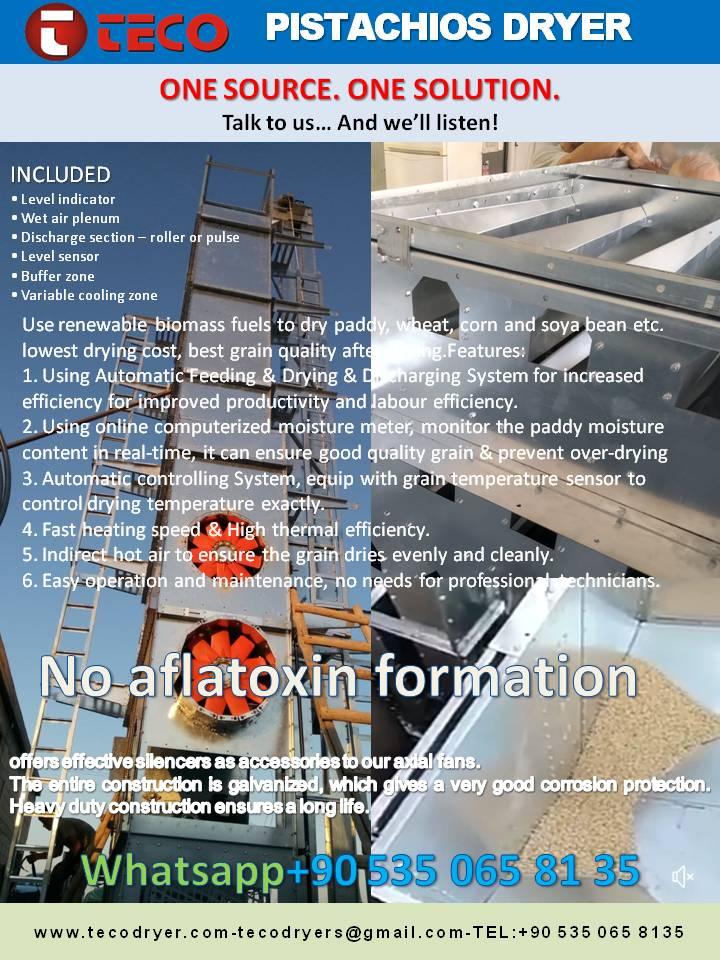

PISTACHIO IS ROASTED AFTER A DRYING PROCESS. BECAUSE THE COLOUR OF PISTACHIO SHELL IS IMPORTANT!

“Experts suggest to roast Pistachio without drying.” This application is recommended for preventing the growth of hazardous molds as aflatoxin on human health. When you roast pistachio without drying, you get a white shell, not brown. However, the end consumer’s preference is dark colour, in other words brown shell. Therefore, the producer roast this product after drying.

WHAT IS THE CURRENT STATUS OF TURKISH PISTACHIO IN THE WORLD MARKET TODAY?

“The US and Iran dominate the world’s production and trade in pistachios.” The t

ANOTHER FACTOR AFFECTING THE EXPORT: AFLATOXIN!

“Does spliting pistachios in water have any impact on aflatoxin?” Moisture content of pistachios and the temparature of storage area are very important. The moisture rate is 50 percent, when it is harvested. It is necessary to lower this moiture content to 7 % as soon as possible (1 to 2 day on average). Otherwise, the formation of the mold called Aflatoxin is unavoidable.

“How are pistachios dried?” After harvesting, pistachios are laid under the sun and left to dry. (Roan Pistachio are commonly havested in August and Red Pistachio in September). If the nut layer is thick more than 2 times, the products on the bottom are visibly molded. – moreover, aflatoxin can not be visible until reaching high levels.

After drying the product, if the moisture content increases to 7 %, the molds caused aflatoxin are activated.

If we dry the product with “dry hulling process”, in other words, if we remove the hull without macerating or carry out this process in an atmosphere with low moisture, the risk of aflatoxin is evenly minimized.

For example, we wet the pistachios a little bit and the moisture content increased to 10 %. We leave the product under the sun in a thin layer for one day. The drying process must not last for days. The shorter drying period, the less risk for aflatoxin.

Another altenative, “you put the products in a water-filled pool” and keep waiting; the moisture content increased to 30-35 %. You hull them and then lay under the sun for drying. Molding risk is high due to the moisture rate.

Then, the exported products are subjected to aflatoxin test and if they find any aflatoxin, these products are immediately destroyed. For this reason, the producer doesn’t prefer overseas sale. One year of labour and capital instantly go to waste.

TURKEY HAS A HIGH VOLUME PRODUCTION, BUT SMALL-SCALE PRODUCER

There are top producers and stockers in America and Iran. Even one company can meet high order quantities. As a result, you can have standart product. However in Turkey, you must supply your order separately. This system is tiring and makes difficult to achive standarts.

In America and Iran, the smallest farmer has 500 acres of land. Average 2 to 3 thousand acres of lands are cultivated. For the same production quantity which is produced by only one company there, 50 to 70 thousand people are required in Turkey.

For Example; Wonderful Pistachios and Almonds. This company has its own fields, factories and markets. In addition, they have organizations affiliated to big companies. These organizations allocate fund for research and development. China is one of the biggest markets. Miss World Beauty Pageant (pistachio competition) is even organized in China.

See below:

www.wonderfulpistachiosandalmonds.com

TURKISH PISTACHIOS ARE NOT SUFFICIENT ADVERTISED

The companies are big and financially strong in America. They allocate exorbinant sums for Promotion and R&D. The Company “Wonderful Pistachio” in America budgets 15 million Dollar. Our institution’s budget, on the other hand, is 100 thousand Dollar. There is also monopolization in the World Trade Network. America run against Iran and we have only 3 percent share in the Global Pistachio Market. While Amerika has 200 thousand tons of export, we don’t even have 10 thousand tons. Turkey has 16 percent of Global Pistachio Production. However, it can only export 3 percent to 5 percent.

Iran started to purchase pistachios from Turkey and process and then export them. By this way, the forecast of 2019 is; it will be over 10 thousand tons and probably reach to 20 thousand tons. But it is a temprorary situation.

Pistachio falls behind due to not having sufficient promotional activities although it has higher aroma.

PRICE FLUCTATION IS ANOTHER REASON AFFECTING THE EXPORT NEGATIVELY!

There isn’t any system regulating the market in Turkey. For example, 5 big industrialists get into the market and made a bulk purchase. In this case, the product price may increase 5 TL or when these companies agreed not to get into the market, it may discount 5 TL. These are the cases that weaken the hand of the companies who want to export.

It is necessary to have min. 6 mounth connection in order to penetrate to the market. Price guaranty must be given.

In conclusion, the problems of pistachios are these:

- Cracking Problem

- Disintegration Problem

- Lack of Capacity (One machine can crack only 60 kg of products per hour. Besides, the tonnage goes down, if the shell is thick.)

- Aflatoxin (It is a moral certainty to face with aflatoxin, if being late for dehumidification.)

- Inadequate Promotion

- Smallness of the cultivated agricultural lands

- Lack of union and cooperative

- The farmers fail to export due to aflatoxin obstacle

- Global Monopolization

- Lack of fund for R&D

- The farmers don’t produce in sufficient tonnage to become mechanichal.

WHEN PEELING RED SHELL, CAN THE STORAGE TIME IN COLD DEPOT BE 1 YEAR?

If the product is well dried and protected from moisture, there will be no problem about storage in cold storage depot. Actually, cold atmosphere is not a must for storage conditions, the moisture is that matters. The rate of moisture must be low. In the atmosphere with low moisture, the farmers can storage their products from 1,5 to 2 years.

However, it is not recommended. Because, the value of aroma will lower when it is stored for a long period.

WHILE CRACKING PISTACHIOS, DOES THE IMPACT CAUSE THE FRUIT TO BE OILED?

No. If you don’t crush the kernel, it is not oiled. There will occur no problem, if you crack it quintessentially.

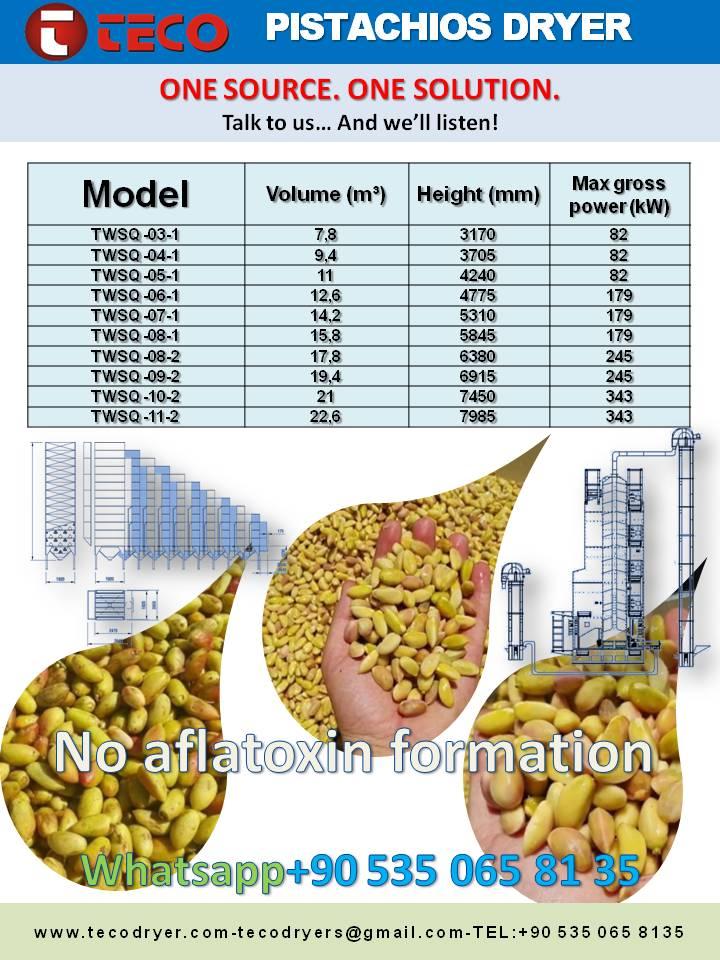

IS THERE ANY DIFFERENCE BETWEEN SUN-DRYING AND DRYING BY MACHINE?

Sun-drying takes 3 days but you can do it by machine in a few hours. The lands belonging to the producers in Turkey is so small and they have only 15-20 sacks product. Therefore, sun-drying is more attractive.

WHAT ARE THE FACTORS AFFECTING CRACKING?

Moisture and size are important. The cracking rate of the Turkish pistachios is lower than the types in America and Iran. They have 80 to 90 percentage of cracking. For example, we have Siirt pistachio. It is more similar to American type. Siirt pistachio has 50 to 60 percentage of cracking rate. But Antep type pistachios are cultivated in Antep.

Moisture content is very important in cracking process. While cracking, they increase the moisture to 15%. If this figure is a little bit lower, the product becomes “kernel” and if this rate is higher, it doesn’t crack. Furthermore, if the fruits wait with 15 percentage of moisture content for 2 or 3 days, aflatoxin becomes unavoidable. However, if you will process pistachios in kolku unit after cracking, you may have no problem.

Pistachios must be salted, roasted or dried until 7 % of moisture content in order to have no problem after cracking.

- Moisturising (15%), Cracking (7%), Roasting (140-150 C°- By this way, the rate of moisture decreases to 2%) Time is important in this process. It should be done in shorter period.

“Kavlama” (Hulling): It means, to peel the red skin covering the shell away by inflating by means of soaking just before processing. It is named after “Tavlama” (roasting) in the lentil peeling process.

WHICH TYPE OF PISTACHIOS CRACKS EASIER?

Cracking Iran and American Type pistachios are easier because they are large-grained. Antep pistachio is more difficult to crack but it has higher aroma. Antep pistachio is sent to Bozhöyük for cracking process. For example; ıf you send 1 ton product for processing, you can obtain only 5 percent of kernel because 28 percent is shell and there is also wastage due to lateral and reversely cracking.

In this rate of 28 percent, there are also those going to waste due to moisture. Moreover, we peel the red skin on the shell away. There are also empty, half empty and weak ones. Namely, you obtain only 700-750 kg roasted product.

WHICH SIZE (MM) OF PISTACHIO SEES VALUE?

That is out of question to see any type of pistachios worthless. Producer grades the products in the screens before roasting process. It can be 9-10 mm, 10-11 mm; it depends on producer. The smallest ones are used as kernel.

WHAT IS THE MEANING OF “KUŞBOKU” (CHICKENSHIT), WHEN CONSIDERING PISTACHIO?

There is a type of matured and appetiser pistachios we get after harvesting and unmatured one we pick nearly a month before harvesting. This very green type which has a high aroma, is called “Boz” and “Kuşboku” (chickenshit) is the name given to the first stage of “Boz”. This pistachio is of good quality and used for dessert sector; it isn’t consumed as appetisers.

The type of Kuşboku has no natural crack because it is harvested early and unmatured. In other words, 100 % is closed.

Details:

- Siirt and Iran Pistachios look like each other.

- According to the TURKSTAT data (Turkish Statistical Institute); many pistachio trees have been planted in current years. The age of maturity of a pistachio tree is 15 years. Our pistachio production will increase 15 years later